Pressure washers are powerful cleaning machines — but they can get tricky when something goes wrong. Low pressure, a leaking hose, pump noise, sudden shut-offs, or soap not working… these issues are common. The good news is that most pressure washer problems can be diagnosed and repaired at home with a simple checklist.

This comprehensive troubleshooting guide walks you through step-by-step instructions for fixing electric and gas pressure washers. You’ll learn how to identify problems early, how to restore lost pressure, how to resolve pump priming issues, how to address engines that won’t start, and what to do when seals or hoses leak.

Whether you’re a homeowner or a professional, this Pressure Washer Troubleshooting: Step-by-Step Checklist will help you get your washer running smoothly again.

Quick Troubleshooting Summary

Before we go deep, here’s a quick summary of common problems:

- Low Pressure: Blocked nozzle, worn pump, air in the system, or incorrect nozzle.

- No Pressure / Pulsing: Clogged inlet filter, kinked hose, low water supply.

- Leaking Pump / Connections: Worn O-rings, loose fittings, cracked hose.

- Engine won’t start (Gas): Old fuel, low oil level, dirty carburetor, bad spark plug.

- Electric Won’t Start: Tripped GFCI, faulty power cord, motor overload.

- Soap Injector Not Working: Incorrect nozzle or clogged chemical tube.

- Overheating/Shut-off: Thermal relief valve activated, long idle, or blocked pump.

Now let’s solve them one by one.

Step 2: Inspect Garden Hose & Pressure Hose

A twisted hose reduces flow.

Checklist:

- Remove all kinks.

- Ensure hose diameter is correct (¾ inch preferred for high-flow systems).

- Check hose connections for leaks.

A leak before the pump reduces pressure significantly.

Step 3: Remove Air from the Pump

Air trapped in a pump causes pulsing or weak pressure.

How to purge air:

- Disconnect the nozzle.

- Run water through the washer for 1–2 minutes before turning the machine on.

- Once a solid stream flows, reconnect the nozzle.

Step 4: Check Water Supply

If the water supply is too low, you’ll lose pressure.

Check:

- Minimum flow rate (GPM) required by your machine.

- Inlet filter screen (clean it).

- Fully open the valve to your home/water source.

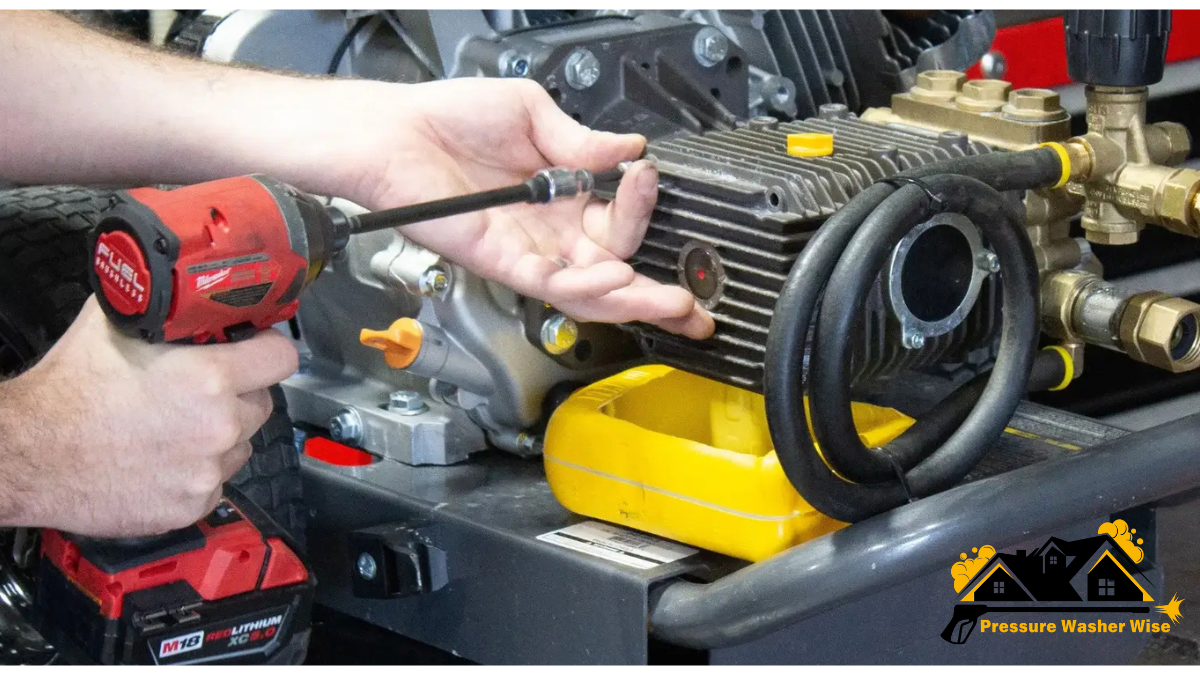

Step 5: Inspect Pump & Unloader Valve

Worn pump seals or a stuck unloader valve can cause a drop in pressure.

Signs of pump problems:

- Oil is leaking from the pump body

- Rough noise

- Water drips during operation

If seals are worn, a pump rebuild or replacement may be needed.

SECTION 2 — No Pressure (Completely Dead Spray)

If your pressure washer sprays no pressure at all, follow this checklist:

Step 1: Check for Clogged Inlet Filter

Debris in the inlet filter stops water from entering the pump.

Fix:

- Remove filter

- Rinse it

- Reinstall

- Test again

Step 2: Check Nozzle Blockage

Completely blocked nozzles stop flow altogether.

Fix:

- Clean nozzle

- Test without nozzle

- Attach the nozzle again

If water flows without a nozzle, the nozzle is the culprit.

Step 3: Inspect Trigger Gun

Trigger guns have internal valves that may jam.

Symptoms:

- Water comes out without pressure

- The trigger feels loose

Fix:

- Remove the hose and nozzle

- Spray WD-40 or a similar lubricant inside the trigger mechanism

- Reconnect and test

Step 4: Unloader Valve Stuck

The unloader valve regulates pressure. If the machine is stuck, it produces no pressure.

Fix:

- Remove unloader

- Clean the piston and spring

- Lubricate

- Reinstall

If it is still not working, a replacement may be required.

SECTION 3 — Gas Pressure Washer Won’t Start

If your gas machine refuses to start, follow these step-by-step:

Step 1: Check Fuel

Old fuel causes dirty starts.

Checklist:

- Use fresh gasoline

- Drain old fuel

- Check the fuel valve and filter

Step 2: Check Oil Level

Some engines have low-oil automatic shut-off systems.

Fix:

- Top up oil to the recommended level

If the oil is too low, the engine won’t fire.

Step 3: Inspect Spark Plug

Dirty or damaged spark plugs prevent ignition.

Fix:

- Remove the spark plug

- Clean carbon buildup

- Replace if the electrode is worn

Step 4: Check Air Filter

Restricted airflow results in a weak or no start.

Fix:

- Clean filter

- Replace the filter if excessively dirty

Step 5: Prime Pump Correctly

Make sure water is flowing before starting the engine.

If the pump runs dry, the machine overheats and fails to build pressure.

Step 6: Carburetor Issues

Old fuel clogs carb jets.

Fix:

- Use carburetor cleaner

- Remove the bowl and clean

- Replace the gasket if needed

Professional carburetor cleaning may be required if the buildup is heavy.

SECTION 4 — Electric Pressure Washer Won’t Start

Electric units fail due to simpler but common issues.

Step 1: Check Power Source

- Plug into a direct outlet (avoid long extension cords)

- Reset the GFCI outlet

- Test the outlet with another device

Step 2: Inspect Power Cord

Look for:

- Cuts

- Burn marks

- Frayed insulation

Replace the cord if damaged.

Step 3: Motor Overload Protection

Electric washers have reset buttons.

Fix:

- Let the machine cool for 10–15 minutes

- Press RESET

- Retry

Step 4: Trigger Gun Switch

Some models won’t start unless the trigger gun is fully connected.

Fix:

- Reconnect trigger handle

- Ensure the switch is fully seated

Step 5: Internal Fuse or Motor Failure

If all else fails, the internal wiring or motor may be the cause of the issue.

Professional repair may be needed.

SECTION 5 — Soap Injector or Foam Not Working

Most soap problems come from a wrong nozzle or a clogged injector.

Step 1: Use the Right Nozzle

Soap mode requires:

- Black soap nozzle OR

- Low-pressure nozzle

High pressure will NOT draw detergent.

Step 2: Check Chemical Tube

Make sure:

- The tube is not cracked

- The filter is not blocked

- Connection is tight

Step 3: Use Proper Soap Concentration

If the mixture is too thick, the injector fails to draw it.

Dilute according to instructions.

Step 4: Check for Air Leaks

Air leaks in the injector line reduce suction.

Fix:

- Tighten clamps

- Replace the chemical tube if brittle

SECTION 6 — Pump Leaking or Making Noise

Pump issues can quickly damage your pressure washer if left unaddressed.

Step 1: Inspect All O-Rings

Leaks usually come from worn O-rings.

Replace:

- Hose connector O-rings

- Wand O-rings

- Pump outlet O-rings

These parts are cheap and easy to install.

Step 2: Pump Overheating

Overheating occurs when:

- The machine runs too long without spraying

- Water flow is restricted

- Unloader valve malfunctioning

Fix:

Avoid letting the pump idle for more than 1–2 minutes. Always spray or shut down.

Step 3: Noisy Pump

Caused by:

- Air entering the pump

- Low water supply

- Worn pump bearings

Purge air, restore water supply, or service pump internally.

Step 4: Water Leak from Pump Body

Indicates worn internal seals.

Fix:

- Seal kit replacement

- Pump rebuild

- Complete pump replacement (for old units)

Triplex pumps can be rebuilt cheaply. Axial pumps are usually replaced.

SECTION 7 — Pressure Washer Vibrates or Pulses

Step 1: Check Water Flow

Low flow causes pulsing.

Step 2: Clean Nozzle

Blocked nozzle = pulsing spray.

Step 3: Examine Unloader Valve

A stuck unloader creates pressure fluctuations.

SECTION 8 — Overheating Problems

Electric and gas washers overheat if:

- Pump runs dry

- Long idle periods

- Chemical blockages

- The thermal relief valve activates

Fix:

- Allow cool-down

- Ensure proper water supply

- Avoid long idleness

SECTION 9 — Maintenance Checklist (Prevent Future Problems)

Use this weekly/monthly maintenance checklist to extend the life of your pressure washer:

Weekly (or after each use):

- Flush detergents from the system

- Clean nozzle

- Inspect hoses & O-rings

- Store indoors

Monthly:

- Clean inlet filters

- Check pump oil (if applicable)

- Tighten fittings

- Lubricate moving parts

Seasonal:

- Replace spark plug (gas)

- Change pump oil (triplex pumps)

- Use pump saver antifreeze if storing for winter

Final Verdict — Easy Troubleshooting Saves Time & Money

Pressure washer trouble doesn’t always mean expensive repair. Most issues, such as low pressure, no-start, leaks, soap failure, or vibration, can be resolved with simple steps outlined in this checklist.

- Start with the easiest checks first (nozzle, hoses, water supply).

- Move to the pump, unloader valve, and engine checks.

- Perform regular maintenance to avoid major failures.

By following this Pressure Washer Troubleshooting: Step-by-Step Checklist, you’ll be able to diagnose problems quickly, restore performance, and keep your pressure washer working smoothly for years.